The LRP™: A Fresh Approach to Sucker-Rod Pumps

Imagine. It’s your first visit to a new well site. You’ve seen the reports…this new installation's a real producer, all right, and you’re anxious to check it out. As you turn down the access road, you expect to see the familiar horse head bobbing over the treetops. You know it must be up ahead, but you can’t see anything. Cresting the hill, you make out in the distance a storage tank, piping, a vent stack…but where’s the pump? In place of the massive walking beam you were expecting to see, there's only a slender metal tube rising from the wellhead. As you pull up nearby, you notice nothing's moving, all is quiet. A quick check reading with your PDA shows that the well is, indeed, pumping fluid. What’s going on here? Welcome to Unico’s latest innovation, the LRP™ Linear Rod Pump.

Imagine. It’s your first visit to a new well site. You’ve seen the reports…this new installation's a real producer, all right, and you’re anxious to check it out. As you turn down the access road, you expect to see the familiar horse head bobbing over the treetops. You know it must be up ahead, but you can’t see anything. Cresting the hill, you make out in the distance a storage tank, piping, a vent stack…but where’s the pump? In place of the massive walking beam you were expecting to see, there's only a slender metal tube rising from the wellhead. As you pull up nearby, you notice nothing's moving, all is quiet. A quick check reading with your PDA shows that the well is, indeed, pumping fluid. What’s going on here? Welcome to Unico’s latest innovation, the LRP™ Linear Rod Pump.

The LRP™ pumping system is revolutionary departure from traditional sucker-rod artificial lift systems. The patent-pending LRP™ system combines variable-speed control, simple mechanics, and industry-leading control software into a compact, lightweight, unobtrusive solution. It’s a fresh approach that provides significant cost and performance benefits over conventional systems.

|

|

|

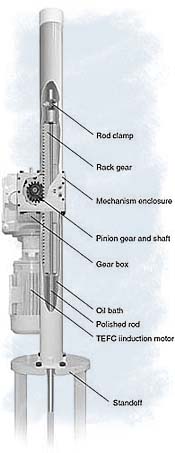

The LRP™ pumping unit mounts directly to the wellhead. The polished rod runs through a channel inside the rack and is suspended from the top by a conventional rod clamp. The rod is allowed to float inside the rack should the pump or rod stick. An induction motor, coupled to the rack-and-pinion mechanism through a gear box, cycles the rack up and down to reciprocate the rod. The rack is lubricated each stroke by submersion into a fully contained oil bath.

|

The LRP™ unit is extremely economical and easy to install. The total system costs a fraction of a comparable jack pump without controls. Transportation, site preparation, and installation costs are minimal. The LRP™ unit mounts directly to the wellhead, eliminating the need for a concrete pad and other special site preparations. It can easily be transported in a pickup truck, handled by two people, and installed with a small rig or picker. Units are up and running within two hours.

With its compact design, the LRP™ unit blends into the landscape where conventional pumps would be offensive or prohibited by regulation. It has a very low profile, no visible moving parts, is quiet, and nondisruptive to the well site. This makes it especially appealing for environmentally sensitive installations.

New High-Output Engine Provides Compact Gas-Powered Lift Package

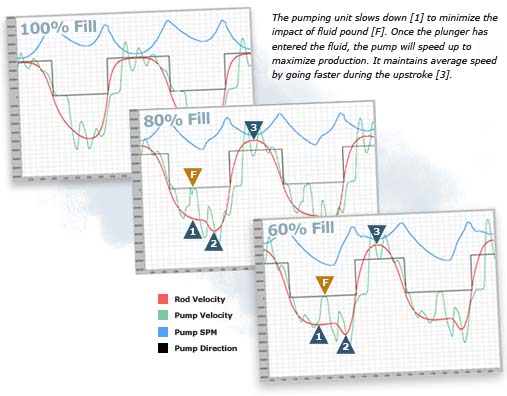

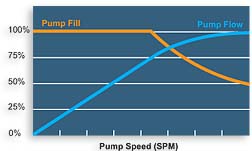

New High-Output Engine Provides Compact Gas-Powered Lift Package Sucker-rod pump production can generally be optimized by operating at partial pump fill percentages. Pump production for a full pump increases in proportion to pumping unit speed. As pump fill drops below 100%, fluid production increases with speed, but at a diminishing rate. Foamy fluid mixtures may require pump fill percentages as low as 60% to maximize oil production. The drawback of operating at reduced pump fills is that it causes fluid pound and associated rod stress.

Sucker-rod pump production can generally be optimized by operating at partial pump fill percentages. Pump production for a full pump increases in proportion to pumping unit speed. As pump fill drops below 100%, fluid production increases with speed, but at a diminishing rate. Foamy fluid mixtures may require pump fill percentages as low as 60% to maximize oil production. The drawback of operating at reduced pump fills is that it causes fluid pound and associated rod stress.