|

|

|

System efficiency and energy costs versus flow for PCP and

ESP systems.

|

There are a number of general conclusions that one might draw from this comparison. Rotaflex units have the greatest energy efficiency due to their long-stroking design. Energy savings for those units, however, may be cancelled by high capital costs relative to other systems. By comparison, ESP energy efficiency is relatively low and falls off dramatically outside of its intended operating range. Sucker rod pumps also lose efficiency at high and low stroking rates, but not as dramatically as ESPs. PCP

efficiency tends to increase in proportion to pumping speed. All pumping systems lose efficiency at low volumes due to leakage effects.

Unico has developed tools for assessing energy issues with artificial lifts that can help you make better decisions regarding the life-cycle costs of an installation. If you would like a detailed analysis, please

contact us.

efficiency tends to increase in proportion to pumping speed. All pumping systems lose efficiency at low volumes due to leakage effects.

efficiency tends to increase in proportion to pumping speed. All pumping systems lose efficiency at low volumes due to leakage effects.

A Comparison of the Energy Efficiency of

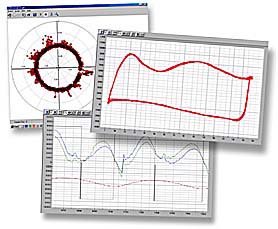

A Comparison of the Energy Efficiency of DriveLink™, Unico's drive-monitoring software for personal computers, has recently been enhanced to provide graphical displays of well performance. The software, which allows a user to setup and monitor up to 99 drives from a Windows-based PC, is typically used to capture well production information, reset control functions, archive setup data, and display operating parameters.

DriveLink™, Unico's drive-monitoring software for personal computers, has recently been enhanced to provide graphical displays of well performance. The software, which allows a user to setup and monitor up to 99 drives from a Windows-based PC, is typically used to capture well production information, reset control functions, archive setup data, and display operating parameters. A software upgrade has been developed for existing pump-jack controls that provides many of the advantages of our latest pump-jack drive systems with the simple change of a chip.

A software upgrade has been developed for existing pump-jack controls that provides many of the advantages of our latest pump-jack drive systems with the simple change of a chip.